Interest in nearshoring to Latin America grows, but US businesses must manage a different supplier risk profile

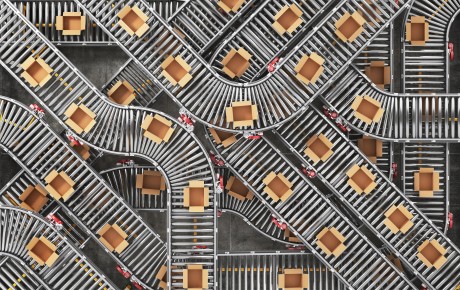

The global supply chain shock inflicted on businesses around the world by the COVID pandemic as well as the geo-political uncertainty of the conflict in Ukraine has led to a renewed interest in nearshoring – moving critical supply chains closer to neighbouring countries. In the US, where many manufacturers might, for example, have relied on component parts coming from China and other parts of Asia, there has been a growth in interest in sourcing from suppliers in Latin America. The opportunity, says the Inter-American Development Bank, is worth a potential US$78 billion in additional exports of goods and services from Latin America and the Caribbean, with Mexico and Brazil leading the pack as nearshoring partners.

While the nearshoring trend will bring many positives, says Amie Townsend – Product Recall Underwriter for Hiscox London Market, nearshoring isn’t risk free. “As the global supply chain evolves to include more nearshoring, changing long-standing supplier relationships brings an increased risk of product recall as new suppliers are ‘bedded in’. For US businesses looking to nearshore with partners in Latin America and the surrounding region, a careful management and mitigation of the risks is essential.”

“As the global supply chain evolves to include more nearshoring, changing long-standing supplier relationships brings an increased risk of product recall as new suppliers are ‘bedded in’. For US businesses looking to nearshore with partners in Latin America and the surrounding region, a careful management and mitigation of the risks is essential.” says Amie Townsend – Product Recall Underwriter

Offshoring trends to nearshoring

Offshoring has been a feature of the global economy for decades – dating back to the 1960s and 1970s – with manufacturing businesses looking to take advantage of cheaper labour costs. In more recent years, offshoring has extended to provide services such as call centres and other administrative processes. But even pre-COVID, there were signs that the offshoring trend was reversing with organisations moving some of their processes either back home or to nearby countries. That switch now looks to be accelerating. A survey by software specialist Capterra, reveals that 88% of small and midsize supply chain businesses are planning to switch some of their suppliers to ones closer to the US, while nearly half (45%) plan to switch all of their suppliers with ones closer to home.

According to a report from crisis management consultancy Control Risks – The Rise of Nearshoring in Latin America: a spotlight on Mexico – the shift from Asia to the Western Hemisphere is being driven by factors including “significant hikes in logistical costs [which] have prompted more businesses to explore opportunities to shrink supply-chain distances, reduce associated costs and mitigate inherent geopolitical risks”. Shipping costs for example rose significantly during and after the pandemic with container freight rates costing over US$10,000 in September 2021. Though rates have settled back businesses will be aware of the susceptibility of rates to future geo-political instability, rising fuel costs, and global events such as pandemics.

Lat Am’s attractions…

For US businesses, Latin America is an obvious geography to choose as a nearshoring location. “Businesses are attracted to lower transport costs from Latin America, greater certainty of delivery, closer time zones, and the possibility to more easily audit and monitor suppliers in person,” says Townsend. Control Risks adds that other advantages include “longstanding bilateral relations with the US and Canada” as well as favourable “social and demographic factors such as a comparatively young working population” and an “ever-growing domestic consumer market”.

“Businesses are attracted to lower transport costs from Latin America, greater certainty of delivery, closer time zones, and the possibility to more easily audit and monitor suppliers in person,” says Townsend

…and its challenges

While there are positives to nearshoring to Latin America, there are still potential pitfalls that businesses will have to look out for and mitigate – some of which are out of an organisation’s control. “As we’ve seen over the years, the political risk in the region is higher which could put operations at risk if governments are unable to maintain stability. Other possible issues include regulatory risks and infrastructure challenges which could mean, for example, power outages impacting operations,” says Townsend. “There is also the micro risk of working with new suppliers. A firm might have been working with a supplier in Asia for decades and have built a solid understanding and relationship. When starting with a new supplier in Latin America, that history isn’t there and a period of settling in could create problems from a quality perspective.”

“As we’ve seen over the years, the political risk in the region is higher which could put operations at risk if governments are unable to maintain stability. Other possible issues include regulatory risks and infrastructure challenges which could mean, for example, power outages impacting operations,” says Townsend.

Thinking of nearshoring to Latin America?

If your business is considering moving operations to Latin America, here are five things you should consider to make sure nearshoring pays dividends and doesn’t lead to unforeseen consequences.

Five top tips:

1: Get robust supplier contracts in place

2: Set up an effective auditing process

3: Establish vendor approval plans

4: Implement a stringent business continuity plan

5: Get familiar with the local regulations

Manage the risks

For a US business planning to nearshore in Latin America, getting the risk management approach right is crucial, Townsend adds, which is where a product recall insurance policy can be invaluable beyond offering straightforward balance sheet protection. “Recognising that no business wants to experience a product recall with all the potential brand damage that comes with such an incident, we offer a percentage of premium back to a client on our product recall policies which they can then use on Control Risks’ services. They can help a US business that’s planning to nearshore minimise the potential for a product recall or other damaging disruption in areas such as getting robust supplier contracts in place, setting up an effective auditing process, and establishing vendor approval plans.”

“While there is no doubt that the opportunity is there for US businesses to create value from nearshoring, it’s about putting in place the systems and processes to make sure the value is effectively realised,” concludes Townsend.